Happiness Guarantee for all requests included

Happiness Guarantee for all requests included

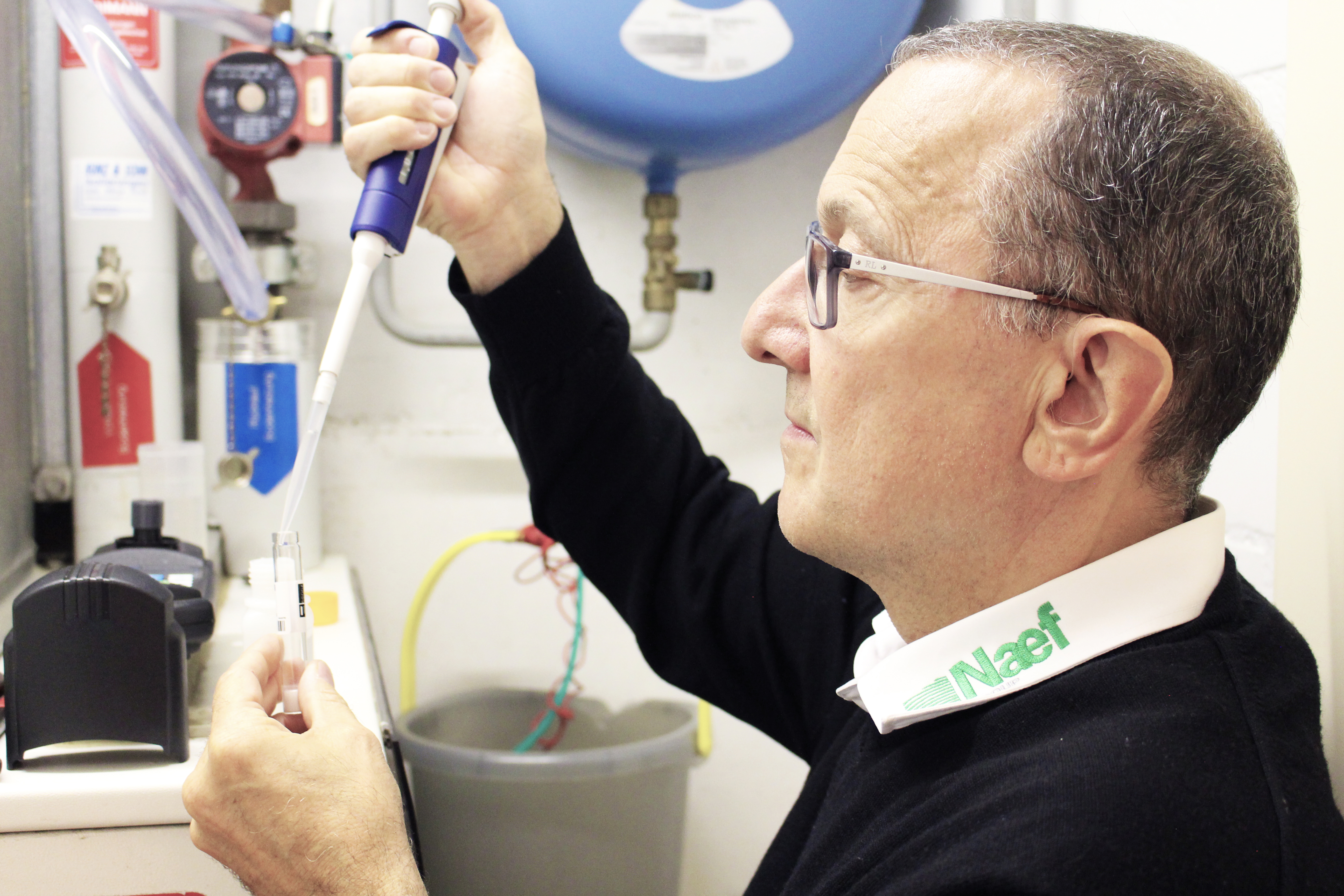

Renovate underfloor heating sustainably with Buildigo and the Naef GROUP

When does underfloor heating need to be renovated and which heating systems are particularly at risk? Here you can read detailed answers to the most frequently asked questions about renovating underfloor heating.

We can tell you right away that almost only underfloor heating systems that were installed between 1970 and 1990 are affected.

Find out more here:

Why does underfloor heating need to be renovated?

Between 1970 and 1990, underfloor heating systems made of simple plastic were often installed, which allows for strong oxygen diffusion. This causes what is known as sludge, as the oxygen molecules attack metal fittings and boilers, which leads to corrosion. The residues of this corrosion settle as sludge in the entire heating circuit, reducing the efficiency of the heating. Plastic becomes increasingly brittle due to temperature fluctuations that occur over the course of the year. The resulting evaporation of stabilizers accelerates the aging of the pipes, which then allow more and more diffusion.

These gradual processes mean that the efficiency of your underfloor heating gets worse year after year - so take proactive action and have a diagnosis and condition analysis carried out.

What does the professional condition analysis of the underfloor heating include?

The condition analysis checks several parameters according to SWKI guidelines in order to assess the condition of the heating. Based on the analysis, you will receive a detailed report and suggestions for necessary renovation measures.

How does renovation work without a construction site?

Here we let our partner, the Naef GROUP, have the floor to explain exactly how a gentle renovation of your underfloor heating is carried out:

"Is renovation necessary and feasible according to the condition analysis? Then we offer you the original for the interior renovation of underfloor heating with the HAT system. We have been using it to sustainably renovate old underfloor heating pipes since 1999 and make them diffusion-tight again in accordance with DIN 4726. Without a construction site.

The pipes to be renovated are first completely dried with specially prepared compressed air. This is followed by the interior cleaning by a gentle and chemical-free fine grinding inside the pipes. With this process we remove sludge residues and encrustations. The pipes are then individually coated seamlessly from the inside with a specially developed coating material. After 48 hours of drying time, this coating creates a new pipe in the pipe, which connects to the existing plastic pipe. The coating protects the old underfloor heating sustainably and makes it diffusion-tight in accordance with the DIN 4726 standard. We are the only company that can provide this proof. We can renovate underfloor heating in the shortest possible time and with a minimum of noise and dirt emissions. Renovating the inside of pipes is around 10 times faster and much cheaper than a total replacement. Your rooms remain habitable during the renovation. With our HAT system, we extend the functionality and durability of your underfloor heating for the next generation."

Naef GROUP

Did you not find what you were looking for?

No worries, you can send an individual request

Do not hesitate and let us know

We are there for you. Feel free to contact us directly by E-Mail with your questions or concerns. We will try to reply immediately. We are available from: Monday to Friday 08:00 – 18:00

What our clients say

The feedback from our clients speaks for itself.